Slate

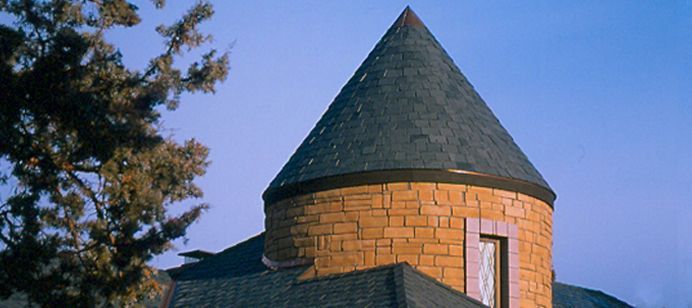

Slate is a dense, tough, durable, natural rock or stone material that is practically nonabsorbent. Standard slate roofs are composed of standard (approximately 3/16 to 1/4 inch thick) commercial slate, having a uniform length and width, and having square tails or butts.

Standard commercial slate may be used to form a variety of designs on the roof and are suitable for many buildings where a long service-life steep-slope roof covering is desirable. Variety in the pattern can be attained by using slate trimmed to a diamond, hexagonal or other pattern or by using random widths.

Graduated slate roofs feature variations in thickness, size and exposure of each course to make the eave to ridge distance look longer, and give the roof a more massive appearance.

Standards for Slate

The American Society of Testing and Materials (ASTM), developed a consensus standard for slate. The C 406 Standard addresses material characteristics, physical properties, and sets sampling procedures. The current C 406 lists three grades: Grade S1 slates are to have specific properties to provide for an expected service life of more than 75 years. Grade S2 slates are to have an expected service life of 40 to 75 years, and Grade S3 slates, 20-40 years.

Roofing Slate Colors

The color of slate is determined by its chemical and mineral composition and because these factors differ in various regions, it is possible to obtain roofing slates in a variety of colors and shades. Exposure to weather causes all slate to change slightly in color and composition. The degree of color change varies with different slates. Those slates that exhibit minimal color change are classified as permanent or unfading slates. Those with a more obvious color change are known as weathering slates. Basic slate colors: black, green, gray, gray green, mottle purple or green, purple and red. When selecting a slate color, the color should be preceded by the word unfading or weathering to designate the color stability of change that may be expected.

Active Slate Quarries

Quarried blocks of slate rock are crosscut into sections, then blocks are split (sculpted) along the grain. Blocks are then split along the cleavage plane into thinner blocks often referred to as "eights." The eights are split along cleavage plane to yield 8 individual rough slates. These rough slates are then trimmed and the nail holes punched to produce the finished roofing slate. The surface texture of slate, after it is split for commercial use depends on the quality and characteristics of the rock from which it was quarried. Many slates split to a smooth, practically even uniform surface while others split to a surface that is rough and uneven. As a result, a wide range of surface textures are available. Some slate contains narrow "ribbons of rock" that are different in chemical composition and color from the principle slate itself. If the chemical composition of these ribbons does not weaken the slate and if the color is not objectionable, ribbon slates are acceptable for use. Slate that has been trimmed so that the ribbons are eliminated is known as clear slate. Slate that contains acceptable ribbons is sold as ribbon stock.